Home >

Corporate News >

NMS Character| After-sales Service Engineer Wu Yihui: Try Your Best to Do Everything

Home >

Corporate News >

NMS Character| After-sales Service Engineer Wu Yihui: Try Your Best to Do Everything

2024.05.25

2024.05.25

In 2013, Wu Yihui joined NMS as an after-sales service engineer. How time flies. Asked about his feelings, personal growth and the changes in NMS over the 11 years, Engineer Wu couldn’t help sharing and told us…

After joining the company, I was assigned to the workshop to quickly understand the equipment, working in the assembly workshop and sheet metal processing workshop for half a year. Firstly, I was very unfamiliar with the equipment structure and parameters. After continuous learning and practice, I gradually accumulated valuable experience concerning the equipment in working principles, installation and debugging, etc.

Partial honors acquired by him

Based on different materials, equipment parameters need to be constantly adjusted and optimized to achieve the best crushing and screening effects on different working conditions; sometimes, when difficult problems were encountered, we had to spend much time finding reasons and racked our brains to improve the equipment based on customer’s needs… When I participated in projects involving installation, debugging, operation and maintenance, my personal abilities were constantly improved. And I met challenges and had a sense of accomplishment in these experiences.

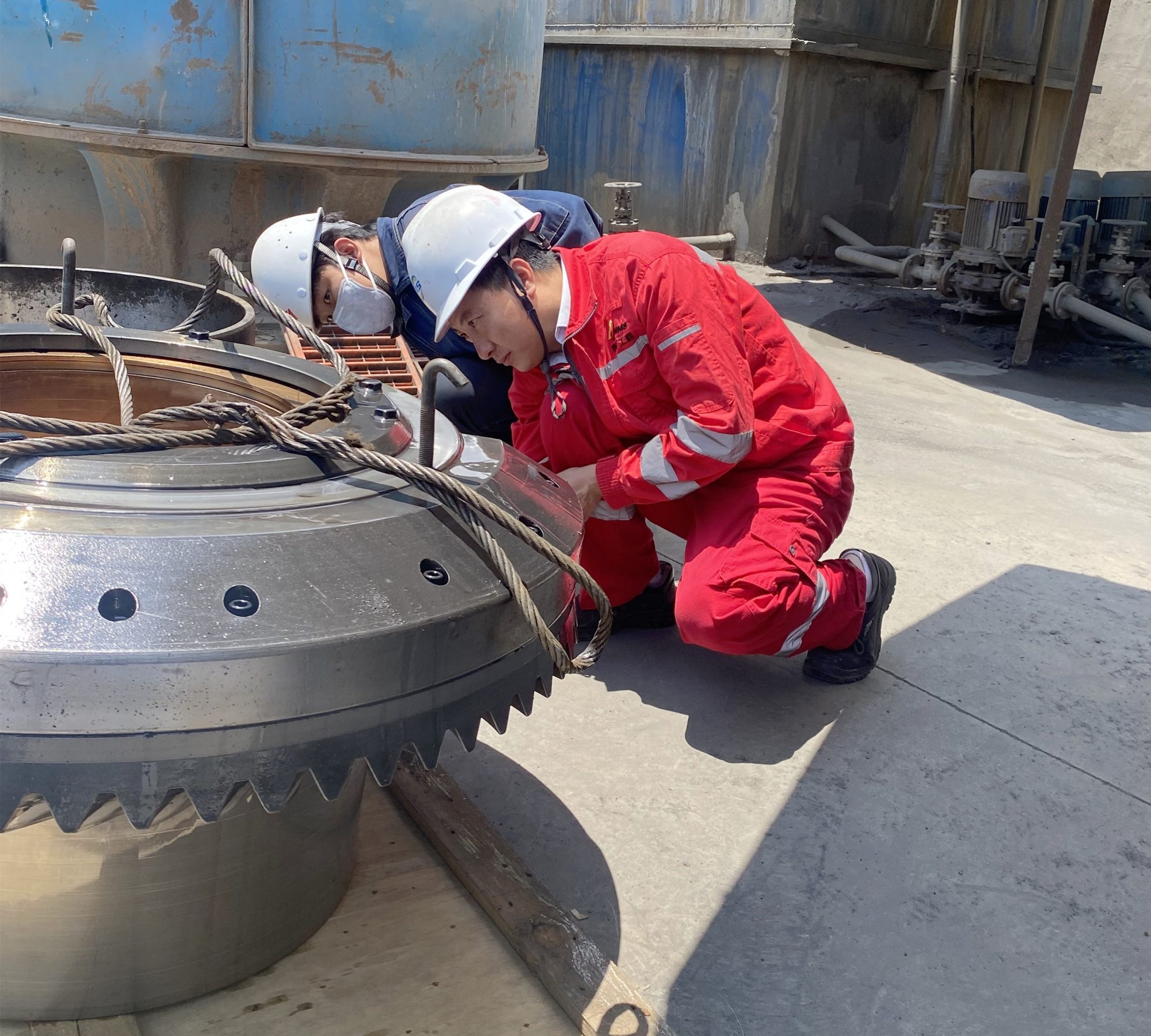

Panzhihua project

In a Panzhihua project, customer’s initial requirement was to produce finished products below 20mm when the customer purchased equipment. In order to increase production, the customer planned to reduce the particle size of the crushed products to below 10mm, so he turned to us for help. Specifically, increasing the overall production capacity needs to ensure the particle size and the established output for helping the next process increase production.

After understanding the customer’s needs, NMS immediately arranged for me to rush to the project site to solve the problem. Based on previous experience and rigorous data calculations, and discussion on feasibility with colleagues responsible for research and development, we finally presented a reliable optimization plan for the customer. The plan was replacing the initial cavity type with the appropriate one in the equipment, successfully helping the customer achieve the goal of reducing costs and increasing efficiency. As a result, the customer is now very supportive that all complete machines and spare parts are from NMS.

In a project in Chongqing, the labyrinth ring of main shaft in our VS impact crusher was locked. We investigated on it for long but could not find the reason. The customer asked us to eat meal and to rest first. However, adhering to the principle of “no rest until the problem is solved”, we were on site to investigate late at night and finally satisfactorily solved the problem through communicating with technicians for advice, which was highly recognized by the customer.

.png)

Karachi project

In addition to domestic projects, I had also participated in multiple oversea projects. In 2015, NMS undertook the Karachi project. I participated in the entire process of the equipment installation, debugging and operation, and stayed there for more than three months. In 2020, I was sent to Guyana to guide the equipment installation and debugging. I originally planned to stay there for 2 months, but ended up staying there for more than 10 months due to COVID-19 pandemic. At that time, the epidemic had just begun to spread. Medical conditions in Guyana were very poor. The locals did not pay enough attention to the epidemic and did not wear masks. Therefore, many people at the project site were infected. Honestly, I was a little scared, but finally I successfully completed the task with personal protective equipment.

I am a colleague of the generation after 00s now. And I have grown from a new employee to an experienced one. I have guided 7 or 8 new recruits and have witnessed many changes in NMS.

In 2021, NMS focused on established tasks and accelerated the transformation from a manufacturing enterprise to a “manufacturing + service” enterprise. NMS separated its aftermarket business and complete machine business and established Jiangxi Gold Intelligent Service Engineering Co., Ltd, as its subsidiary to specialize in providing services such as equipment maintenance, technical consulting, intelligent operation and maintenance, equipment repair and manufacturing, technology optimization for production line, spare parts supply, consumables supply, and financial support.

With the establishment of Jiangxi Gold Intelligent Service Engineering Co., Ltd, our after-sales service has become more systematic, precise and professional than before, and the service content has been improved. In the past, we only simply installed and maintained equipment. Now we help customers solve problems from a systematic perspective such as process design, and are committed to providing customers with solutions through full life cycle. At the same time, we carry out regular equipment inspections every month to troubleshoot problems to ensure the normal operation of the project.

In terms of personnel, NMS originally only had 7 or 8 after-sales service engineers but now after-sales service engineers have increased to nearly 60; after-sales service engineers were mainly from vocational schools in the past but are from undergraduate institutions now. At the same time, many technical experts and technical engineers were introduced to form an expert committee to provide professional technical support for projects. The upgrade of transportation has promoted the improvement of service response speed. In the past, we basically went to the project site on foot, by train or bus or motorcycle. Recently almost every after-sales service engineer is equipped with a car, and the service response time has been reduced from originally 48 hours to 24 hours, resulting in greatly improving after-sales service efficiency. The used tools have also changed a lot. In the past, we mainly used basic measurement tools such as outside micrometers, inside micrometers, and vernier scale. Now all after-sales service engineers are equipped with intelligent tools, such as 3D projection measuring instruments, vibrometers, resulting in the improved accuracy of measured data and the increased work efficiency.

Spare parts warehouse at abroad

Spare parts warehouse in South Africa

In terms of spare parts, NMS has optimized its production schedulers and production processes. And the production efficiency has been greatly improved. In the past, it took half a month to 30 days to produce a certain spare part, but now the certain spare part can arrive at the project site in 5 to 7 days. At the same time, NMS has spare parts warehouses in many domestic places, such as Xi’an, Panzhihua, and Botou, and in many oversea countries and regions such as South Africa and Australia (under preparation). In addition, NMS has established spare parts warehouses in multiple project divisions, which greatly facilitates after-sales service and can effectively help customers reduce production losses caused by equipment downtime. We believe that with the completion of the industrialization project of key spare parts for our high-performance intelligent crushers, the quality and price of spare parts will be further optimized.

Intelligent O&M center

In addition, NMS has established an intelligent operation and maintenance center. Through this platform, we can provide supportive services such as collecting real-time equipment data, monitoring equipment operating status, remote maintenance guidance, full life cycle management, intelligent analysis of operating data, and predictive analysis. Once abnormal data is discovered, we will timely communicate with people at the site or rush to the site to investigate the cause of malfunction, to prevent fault impact extension, and to help customers reduce costs and increase efficiency.

Helping customers solve technical bottlenecks makes me very proud. Having an “altruistic spirit” and working hard to solve problems for customers are the qualities that every after-sales service engineer should have. As an after-sales service engineer, you need to be perseverant and patient, to be able to withstand tests, to humbly accept criticism, and frequently to calmly reflect for finding the breakthrough point of problems. Teams must closely work together to overcome on-site problems and share experience and knowledge with each other in order to achieve the goal of providing good customer service.

Working as an after-sales service engineer, it is normal to spend little time when families gather. I sometimes have to get off the car in the midway and rush to the site when I receive a call before I arrive home. Occasionally I have just arrived home and slept one night, I have to go to the site again the next day. So I am very grateful to my wife for her support, tolerance, and taking care of family over these years. I will definitely work hard for her.

“Keep doing everything that you think is right and try your best to do it.” I am very grateful for every opportunity and every customer’s support, which allows me to grow into a professional service engineer. Faced with the lasting developing crushing and screening industry, I will continue to learn and to improve my abilities for better adapting myself to changes and needs in this industry, for striving to quickly solve customers’ problems with professional and optimal solutions, and for trying my best to boost the development of NMS. (Liu Xiaohan)