Home >

Corporate News >

NMS Shines at Xinjiang Mining Expo, Empowering the Future of Mining with Innovative Technologies

Home >

Corporate News >

NMS Shines at Xinjiang Mining Expo, Empowering the Future of Mining with Innovative Technologies

2025.07.25

2025.07.25

On July 18, the 15th China Xinjiang International Mining and Equipment Expo and the 20th China Xinjiang International Coal Industry Expo officially opened in Urumqi. Centered on the theme of “New-Quality Productive Forces and Global Mining Cooperation,” Nanchang Mineral Systems Co., Ltd. (NMS) made a high-profile appearance at Booth A08 in Hall 1, showcasing its cutting-edge equipment and solutions that enable efficient, intelligent, and sustainable development in the mining industry.

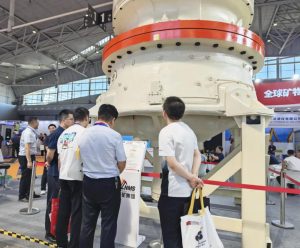

Innovative Equipment Driving Efficient Mining

The spotlight at the booth was undoubtedly on the CC800—NMS’s flagship large-scale single-cylinder hydraulic cone crusher. Designed based on the lamination crushing principle, the CC800 stood out for its outstanding performance and advanced engineering.

Tailored for large-scale metal mines and hard rock crushing, the CC800 delivers high capacity, excellent crushing efficiency, and reduced energy consumption—15–30% lower than traditional spring cone crushers. It features a pioneering six-channel independent positive-pressure dustproof system, a high-power blower, and a long-life dust seal, which greatly extends lubricant life and effectively prevents dust intrusion. Equipped with a new-generation electric overflow valve overload protection system and the AutoRun intelligent control system, the machine ensures faster response and stronger protection. Highly versatile, a single unit can accommodate nine interchangeable cavity types by replacing the moving and fixed cone liners, with 13 available eccentric settings to suit diverse application scenarios. Its horizontal shaft employs a dual oil-seal system for improved sealing and extended bearing life. Modular design and hydraulic disassembly significantly simplify liner replacement. The standard AutoRun system offers smart features such as constant discharge setting, liner life prediction, and real-time alarms.

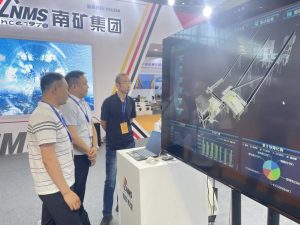

Smart O&M Enabling Digital Mines

During the exhibition, NMS also presented its advanced intelligent operation & maintenance (O&M) platform and successful project cases. Developed in May 2021 through in-depth collaboration with a leading U.S. industrial firm, the system is built on Industrial Internet of Things (IIoT) technology. The platform supports real-time equipment data collection, operating condition monitoring, remote maintenance guidance, full lifecycle management, intelligent data analysis, and predictive maintenance. By providing digital delivery and integrated O&M services, it helps mining enterprises reduce costs and enhance operational efficiency. This platform has already been deployed across multiple projects and is a key pillar in building the smart mines of the future.

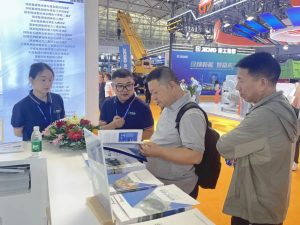

Premium Wear-Resistant Products Solving Screening Challenges

Another highlight was the high-performance MDI polyurethane anti-clogging screen panels from NMS subsidiary Nanchang NMS New Technology Material Co., Ltd., attracting significant attention and showcasing NMS’s deep expertise in the wear parts domain.

Compared to traditional screens, the MDI polyurethane screens excel in wear resistance, elasticity, clogging prevention, screening efficiency, and service life. Made with imported MDI materials, the panels feature adjustable hardness to suit different material types. Their high open area and excellent rebound properties significantly enhance efficiency and lifespan. A internal hook-lock installation design allows quick replacements, and a diverter block optimizes material flow. Optional water dams are available for improved dewatering. As a professional polyurethane screen supplier, Nanchang NMS New Technology Material has served over 2,000 customers globally. Its products are widely used by leading domestic mining companies including Makeng Mining (Fujian), Yunnan Tin Group, Zijin Mining, China National Gold Group, Wuyang Mining, Ma Steel Mining, and Jiangxi Tungsten, and have also entered international markets.

Open Collaboration for a Smarter Future

NMS’s partner, Hunan Jumper Technology Co., Ltd., also participated in the event, showcasing its industry-leading intelligent optical sorting technology and offering attendees an experience of cutting-edge mining technologies.

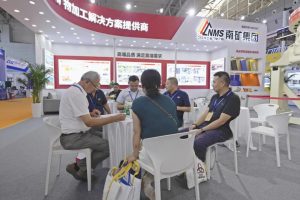

At the expo, NMS’s team of technical experts held in-depth discussions with industry peers from around the world, exploring how to apply “new-quality productive forces” in practical mining operations. Tailored and high-efficiency smart solutions were offered based on the specific needs of each customer.

To further enhance engagement, NMS also hosted a lucky draw at the booth, attracting enthusiastic participation and creating a vibrant on-site atmosphere.

By participating in the Xinjiang Mining Expo, NMS demonstrated its deep expertise and leading edge across key areas such as advanced intelligent crushing equipment, digital O&M systems, high-performance wear-resistant materials, and intelligent optical sorting. This exhibition embodied NMS’s commitment to translating new-quality productive forces into real-world mining applications.

Looking ahead, NMS will continue to focus on technological innovation and global partnerships, striving to provide more advanced, reliable, and intelligent integrated solutions for mines worldwide. Together with industry partners, NMS is charting a new course for smart mining and contributing to a more sustainable mining future.