2024.03.14

2024.03.14

Xiaoqing Xiong, born in 1966 in Nanchang, Jiangxi Province. His father was a mechanic in the metalworking shop of Nanchang Mining Machinery Factory (formerly known as NMS). In 1984, Xiaoqing Xiong entered the machinery factory as an apprentice, thus becoming a “second-generation miner.” That year, he was exactly 18 years old, and today, he has been working in the Nanchang Mineral Systems Co., Ltd. (hereinafter referred to as “NMS”) for a full 40 years.

18-year-old Xiaoqing Xiong and Present Him

Memories of NMS

According to Xiaoqing Xiong’s recollection, at that time, the Nanchang Mining Machinery Factory was located at the foot of Ziqing Mountain in Nanchang, mainly processing belt conveyors. At the same time, the factory also product vibrating screens for the coal industry, but initially, NMS only made small screens measuring 1250mm in width and 3600mm in length.

Relying on the interest-free loans provided by state support policies, the Nanchang Mining Machinery Factory purchased land in Wanli District. In 1985, the factory relocated from Ziqing Mountain to Wanli, and massively introduced production machinery, including 2.5-meter vertical lathes, 3.5-meter vertical lathes, 6-meter planing machines, gear hobbing machines, outer edge grinders, and other semi-automatic processing equipment. In 1987, the enterprise introduced its first officially allocated college graduate. From 1990 to 1992, it continued to recruit nearly thirty college graduates for three consecutive years. With the increase in technical personnel, the company’s product development capabilities and management level improved significantly. Under the leadership of Director Dengtang Gan, a graduate of the Beijing Mining Institute (predecessor of China University of Mining and Technology) with work experience at the Tangshan Design Institute, the NanKuang Group successively developed equipment such as circular vibrating screens, wind pelletizers, cone crushers, and spring screens. Among them, the development projects of the circular vibrating screen and wind pelletizer were approved as national projects.

Employees with the Newly Acquired Gear Hobbing Machine in 1985

Xiaoqing Xiong vaguely remembers that in 1986, the first YKR3052 circular vibrating screen of NMS was successfully developed. In 1988, 2 YKR3052 circular vibrating screens were sold to the Fenghuangshan Coal Mine. These two devices were used side by side with German screens for 8 years, which made the vibrating screens produced by NMS gain some reputation in the coal industry. With the development of the Three Gorges project, NMS’s screening machines have firmly established themselves in the national water conservancy and hydropower industry, becoming a symbol of quality among domestic screening equipment.

Test Run of Vibrating Screen in 1986

In 2003, NMS underwent restructuring, and following the restructuring, wages were paid according to the principle of “more work, more pay.” Looking back on those times, Xiaoqing Xiong is very happy. He proudly mentioned that his salary increased more than four times in the second year after the restructuring, and everyone was filled with enthusiasm. Subsequently, the company extensively renovated the factory buildings and office buildings and introduced new equipment. “Originally, we used semi-automatic equipment, which was replaced with fully automatic equipment. This made our production more standardized and easier, increased precision, and improved product compliance. It can be said that both speed and quality have improved.“

Passing Down Skills

Speaking of technical improvement, Xiaoqing Xiong mentioned that he initially worked as an apprentice in the sheet metal workshop, responsible for sheet metal welding. At that time, he was not yet called Master Xiong; everyone called him Little Xiong. “Min Deng, Rongguo Hu …“ Master Xiong listed a string of names, saying that these people in the sheet metal workshop were his mentors. “At the beginning, I didn’t know anything, but I was very eager to learn. I asked when I didn’t understand, practiced a lot, and everyone generously taught me. Gradually, I got the hang of it.“ However, Master Xiong said that the most difficult thing for him, with only a junior high school education, was identifying drawings. At that time, NMS encouraged employees to improve themselves. For employees who wanted to attend night school, they could apply for a reduction of 3-4 years’ tuition fees, which was about 30 yuan per semester. Taking advantage of this opportunity, Master Xiong signed up to study mechanical drawing. He practiced during the day and studied at night, greatly improving his professional skills.

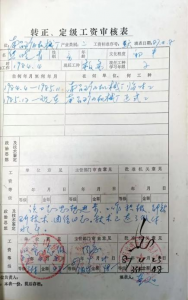

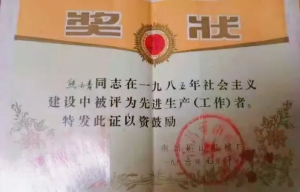

In late 1985, Xiaoqing Xiong passed the examination and was graded as a third-level worker (the levels range from one to eight), and due to his outstanding performance, he was converted to a formal employee ahead of schedule. At that time, it was stipulated by the state that apprentices needed 3 years to become formal employees, but he, through his own efforts, achieved this in just over a year and was named the advanced producer (worker) of that year.

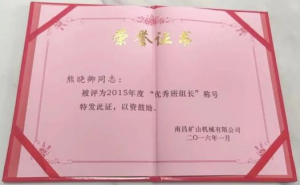

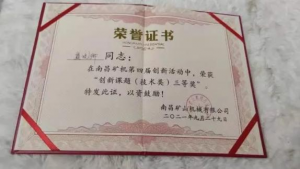

In the sheet metal workshop, Xiaoqing Xiong has worked for 35 years. He has mastered the production of various sheet metal parts such as vibrating screens, vertical shaft crushers, impact crushers, jaw crushers, cone crushers, feeders, rod mills, sand washers, and classifiers. Gradually, he became a team leader and also a mentor. According to his recollection, starting from 1988, he has trained approximately 10 apprentices, helping the company cultivate a group of skilled sheet metal workers. For the daily work of the workshop, Xiaoqing Xiong often brainstormed and proposed innovative and practical suggestions for reasonable improvements, effectively enhancing production efficiency and reducing costs. He has been awarded various honors, including the Outstanding Team Leader of 2015, the “Model Worker for Rationalization Proposals” of 2019, the Craftsmanship Award of NMS in 2020, the Star of Organization and Rectification of 2021, the Third Prize of International NMS in 2022, and the Third Prize of Innovation Activities in the Fourth Session for Innovation Projects (Technical Category).

Do Things Well

In 2014, Xiaoqing Xiong took on the responsibility of equipment installation. This marked his first experience traveling abroad, as he went to Guinea to install jaw crushers and screens. To prepare for this journey, he even self-studied some basic English greetings. However, his first trip abroad was not without challenges. At that time, Guinea was grappling with an outbreak of the deadly Ebola virus, with mortality rates ranging from 60% to 90%. After receiving vaccinations in China, Xiaoqing Xiong, along with two colleagues, embarked on the journey to Guinea with apprehension. Through their mutual cooperation, they ultimately succeeded in completing the installation task despite the challenging circumstances.

Since then, he has been involved in the installation, commissioning, and trial operation of complete sets of equipment for projects both domestically and internationally. His work has taken him from various locations in China, such as Hong’an in Hubei, Liupanshui in Guizhou, Lishui in Zhejiang, and Chongqing, to countries and regions overseas, including Guinea, Karachi, Zimbabwe, and Namibia. As the equipment from NMS is sold to more and more places, Xiaoqing Xiong’s footprint has begun to spread far and wide. When asked about the most memorable project he has worked on, he immediately responded, “That would undoubtedly be the mobile station project in Namibia.” Speaking about this project, Xiaoqing Xiong visibly becomes excited, saying, “The original plan was for us to stay in Namibia for 2 months, but we ended up staying there for 14 months.”

The Namibia Mobile Screening and Crushing Project

The Namibia Mobile Screening and Crushing Project was won by NMS after competing with global crushing and screening giants. This project involves using mining waste for infrastructure construction such as mine base, access roads, waste rock dumps, tailings dam embankments, and filling of blasting holes with sand and gravel aggregates. Under the commission of the client, NMS dispatched a service team to guide system operations and train local operators and maintenance personnel, with Xiaoqing Xiong being one of them. The project commenced construction and installation in September 2014, went through trial operation in March 2015, and was delivered for use in October 2015. The project’s capacity and various individual performance indicators fully met the acceptance criteria stipulated in the contract. “At that time, we lived in simple sheds, the food was not quite to our taste, but there was a Chinese canteen set up there, and all the Chinese people on the project liked to eat there. The client was very satisfied with our equipment and services, and I myself felt very happy.”

During the Chinese New Year, Xiaoqing Xiong (far left) and other members of the NMS service team gathered for a meal in the project shed in Namibia

“Good work leads to good results” is Xiaoqing Xiong’s life motto. “Improving the living standards of my family through personal abilities” is what Xiaoqing Xiong is most proud of. Like all Chinese workers, Xiaoqing Xiong is ordinary in a way, diligently working in one position for 40 years. Yet, he is also extraordinary, as his craftsmanship spirit will continue to be inherited within NMS.

With only two years left until retirement, Xiaoqing Xiong’s passion for learning suggests that he may not slow down after retirement, as he might busy himself with some new pursuits. (Xiaohan Liu)