Home >

Corporate News >

Debut! NMS Intelligent Operation & Maintenance Platform Helps to Upgrade Digitization and Intellectualization

Home >

Corporate News >

Debut! NMS Intelligent Operation & Maintenance Platform Helps to Upgrade Digitization and Intellectualization

2021.10.30

2021.10.30

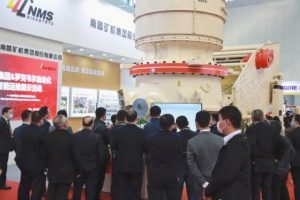

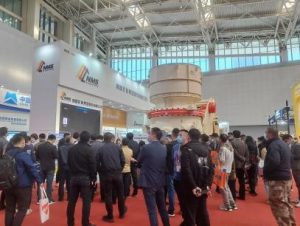

“What you see now is the real-time monitoring of CC300 cone crusher thousands of miles away, and the equipment operation data are being transmitted from Nanchang, Jiangxi Province to our platform in Tianjin.” At 2021 (23rd) China International Mining Exhibition, NMS booth was crowded. NMS was showing the guests its latest intelligent operation & maintenance platform.

It is understood that this is the debut of intelligent operation & maintenance platform of NMS. The platform is established based on Rockwell Industrial Internet of Things (IIOT) technology and can provide service support such as equipment real-time data acquisition, equipment operation status monitoring, remote maintenance guidance, whole life cycle management, intelligent analysis and predictive analysis of operation data to provide customers with digital delivery and integrated operation & maintenance to help customers reduce costs and increase efficiency.

Through the monitoring of equipment on the platform, it can predict equipment faults and the remaining service life of spare parts, reduce abnormal downtime, enable users to realize active maintenance, improve equipment OEE, reduce early purchase and over purchase of spare parts, promote spare parts inventory turnover, reduce capital occupation, reduce cost and increase efficiency for customers. It can monitor equipment status and automatically warn potential faults for pre-prevention management, enhance the planning of service and improve efficiency and experience. Combined with AR technology, it can realize remote operation and maintenance training or installation and maintenance guidance of equipment, and reduce wait time. Simultaneously, the analysis of product faults through intelligent operation and maintenance platform, together with the internal information system, can help NMS achieve quality traceability, optimize product design, processing technology, manufacturing and other links to continuously improve product performance and provide customers with more superior products and solutions.

Display of NMS intelligent operation & maintenance

The intelligent operation & maintenance platform is composed of four parts. First is visualization, it includes equipment map, trend center, screen and monitoring. It can check the distribution, real-time operation screen and operation data to monitor equipment status. Second is equipment itself, it can check the account, solutions to common issues and digital documents. Third is repair, it can check the records, and can quickly apply for repair through App, then, after-sales staff will be notified by the APP. Fourth is operation & maintenance, it can formulate maintenance and spot checking plans.

Gong Youliang, President of NMS (left), and Dai Pengfei, Deputy President of Rockwell Automation, Greater China (right)

On the same day, President Gong attended the event and delivered a speech. He introduced in his speech that in recent years, NMS has focused on the goal of building an intelligent manufacturing and service enterprise, spared no effort to build informatization, digitization and intellectualization, and accelerated the intelligent and digital transformation. The intelligent operation & maintenance platform was not only the phased achievement of intellectualization, but also an important step towards digitization. The implementation of the project would help NMS transform from a manufacturing enterprise to a manufacturing and service one.

He said that intelligent and digital transformation was the starting points for NMS transformation, upgrading and high-quality development. NMS would continue to optimize services, strengthen guarantee, improve product performance, and make its customers feel the convenience brought by intellectualization. We would work harder and continue to accelerate the pace of digital and intelligent transformation to promote the high-quality development and efficiency of the mining industry.

Companies and guests from 30 countries and regions participated in 2021 (23rd) China International Mining Exhibition, which opened on October 21 and lasted to October 23. The large-scale equipment CC800 single cylinder hydraulic cone crusher and 3BS3282C banana screen from NMS were hot in the exhibition, and an endless stream of people were present. The interactive activities such as prize Q & A and lucky draw were held during the exhibition.