Home >

Corporate News >

NMS MSP200 Sand-making Tower Wins the 1st Prize of 2022 Jiangxi Excellent New Product

Home >

Corporate News >

NMS MSP200 Sand-making Tower Wins the 1st Prize of 2022 Jiangxi Excellent New Product

2023.06.09

2023.06.09

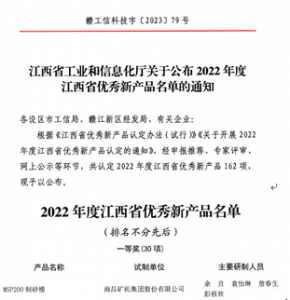

Recently, the Department of Industry and Information Technology of Jiangxi Province has issued a notice on the announcement of the list of 2022 Jiangxi excellent new product. Among them, MSP200 sand-making tower developed by NMS wins the first prize.

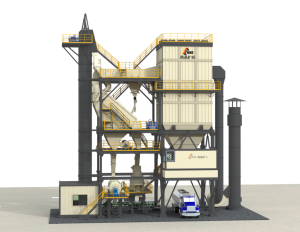

In response to the low sand forming rate, high powder forming rate, unreasonable aggregates gradation and dust pollution that occur in the traditional manufactured sand production, NMS has launched MSP high-efficiency sand-making tower with its own experience through years of research on technology.

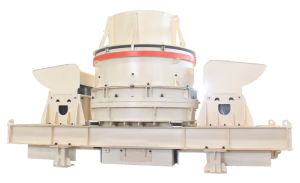

MSP200 sand-making tower is equipped with VSD dual chamber vertical shaft crusher and HFS/V hydraulic high-frequency screen independently developed by NMS, which has higher and stable sand forming rate and screening efficiency. Comparing with ordinary vertical shaft crusher, the sand forming rate of VSD dual chamber vertical shaft crusher can be increased by 25.4%, and the powder content in sand with size less than 5mm can be reduced by 2.6%. The high-frequency vibrator of HFS/V hydraulic high-frequency screen acts on the screen mesh directly, and the processing capacity is 2.5-3 times that of a regular circular vibration screen when screening fine materials.

VSD dual chamber vertical shaft crusher

HFS/V hydraulic high-frequency screen

According to different materials, the MSP200 sand-making tower has two processes for free selection, namely screening before crushing and screening after crushing, without changing the overall layout. This can effectively utilize production capacity of all equipment in the system, while avoiding excessive powder and reducing system’s load.

MSP200 sand-making tower adopts a unique rain curtain powder selection, which integrates screening and powder selection. The internal space of powder selection is large, the fine powder is fully dispersed and flying, so the efficiency is high. At the same time, it is equipped with an efficient variable frequency fan, which can flexibly adjust air volume and speed, ensuring the product quality. The sand-making tower uses a pulse bag dust collection system for centralized collection, and adds collection points at multiple drop points inside the building, so that the tower can meet environmental requirements without separate packaging.

For the layout, HPS/V hydraulic high-frequency screen is at the top as its non-vibrating frames, and VSD dual chamber vertical shaft crusher with heavy weight and easy vibration on the ground, reducing the load-bearing capacity of the tower and ensuring that the entire tower is more stable and reliable compared to traditional one. In addition, the tower adopts a DCS centralized control system, achieving centralized control of all equipment and online real-time monitoring. The tower adopts a modular design method, which divides each component into several modules in a reasonable manner, effectively reducing on-site installation difficulty and shortening installation time.

It is worth mentioning that several sets of NMS MSP efficient sand making tower have been put into the market. Through tracking and analyzing product processing capacity, sand-making performance and customer feedback, it has been confirmed that its various indicators have met the requirements of domestic sand-making tower, and have achieved excellent performance in maintenance, sealing, dust treatment and sand forming rate, winning a good market reputation.

As one of the leading domestic technology and service providers, NMS will continue to fully play a demonstration role in the future, continuously increase investment in new product research and development, continuously develop new products with high technological content, high added value and good market prospects, promote industrial innovation driven development, and make positive contributions to promoting high-quality economic and social development.