2023.11.08

2023.11.08

A concept that awakens over 2,000 years of cultural memory; an initiative that ignites the enthusiasm of more than 150 countries to achieve their dreams. In the autumn of 2013, Xi Jinping — PRC president, during his visits to Kazakhstan and Indonesia, successively proposed the significant initiatives of jointly building the Silk Road Economic Belt and the 21st-Century Maritime Silk Road. In 2023, we celebrate the 10th anniversary of the “Belt and Road” initiative.

Over the past decade, Nanchang Mineral Systems Co., Ltd. (hereinafter referred to as “NMS”) has actively responded to the “Belt and Road” initiative, resolutely implemented the “Going Global” international business strategy, and made remarkable achievements in the construction of “International NMS”.

As early as 2005, NMS had set its sights on the layout of overseas markets. NMS specifically established Shanghai Kaicai Industrial Co., Ltd. and formulated the corporate vision of becoming an “internationally renowned brand” with an international strategic perspective. NMS continuously expanded their overseas sales and service networks. In December 2016, Nanchang Mining Machinery Crushing and Screening Co., Ltd. (Malaysia) was established. In January 2017, Nanchang Mining Machinery Africa was founded. In July 2019, Nanchang Mining Machinery Australia was established. In November 2019, Nanchang Mining Machinery Moscow Branch was established. In January 2019,NMS also set up a research and development center in Sweden to support innovation in the company.

NMS’s Site in Laos Project

Riding the “Belt and Road” initiative, NMS’s professional localization service system and reliable quality products have gradually gained more recognition in the international market. NMS’s equipment has been exported to countries and regions such as Russia, South Africa, Zimbabwe, Botswana, Namibia, Malaysia, Indonesia, Laos, Pakistan, Saudi Arabia, Iran, Serbia, and more. It has also gradually entered the European and American markets, establishing collaborations with several Fortune Global 500 companies.

Professional Leading Integrity First

“South Africa was the first African country to sign a cooperation document with China for the joint construction of the ‘Belt and Road.’ For 13 consecutive years, it has been China’s largest trading partner in Africa and one of the countries with the most Chinese investment stock in Africa. In 2017, NMS established its African company in Johannesburg, Republic of South Africa, while also setting up a warehouse base that includes main machines and components to serve central and southern Africa.”

NMS’s Warehouse Base in South Africa

In 2018, after numerous inspections, the customer of the South African KMR project chose NMS to undertake this EPS project. The two parties signed a contract, and the cooperation included engineering design, equipment supply, guidance for installation and commissioning services, etc. In August 2019, the first batch of equipment arrived at the project site in South Africa, followed by the second batch in November. In early 2020, as the project entered the installation and commissioning phase, the unexpected the COVID-19 pandemic caught everyone off guard.

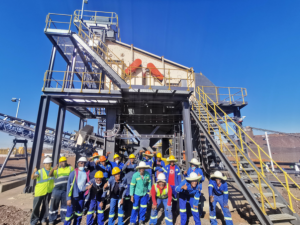

NMS’s Site in South Africa Project

In order to ensure the project’s timely construction, in February of the same year, a team of six from NMS’s overseas department, including project managers, sales, technical, after-sales, finance, bid farewell to their families and resolutely headed to South Africa. After the quarantine was lifted, with proper epidemic prevention measures in place, they worked tirelessly day and night to ensure the successful installation and commissioning of the equipment. Adhering to the philosophy of “Leading Professional, Integrity First,” NMS took action to fulfill its commitments, meet the deadline, and earned the gratitude and praise of the customer.

Customized Processes to Meet Your Needs

The 2x500t/h aggregate project in Karachi, Sindh Province, Pakistan, processes material consisting of sandy limestone with a high impurity content. During production, a significant amount of fines is generated, and the project has stringent requirements for product gradation, mud content, and fines content, with a strict limit of 3% for the fines content in manufactured sand. Subsequently, after multiple on-site inspections and extensive communication, engineers from NMS developed a “multi-stage fines removal, dry-wet combination” process tailored to the characteristics of hard, highly adsorptive rock. This innovation has successfully achieved water conservation and effective control of fines content. By utilizing medium and fine crushing cone crushers and adjusting the material separation devices, the production can seamlessly switch between producing coarse aggregates of different specifications, such as 16-31.5mm or 16-26.5mm. Simultaneously, this process controls the entry of some or all small stones into the rear vertical shaft crusher, facilitating precise shaping and optimizing gradation.

NMS’s Site in Pakistan Project

Due to water scarcity at the construction site and persistent strong winds of seven to eight or higher, dust control during production and processing posed a challenge. NMS addressed this issue by implementing various measures, including dry dust collection, windbreak walls, and localized dust suppression using water mist. These actions ensured compliance with the site’s dust control requirements. Simultaneously, the wastewater generated from washing the final aggregates and manufactured sand underwent effective concentration and sedimentation using a thickener. This approach achieved a water recycling rate of over 92%, effectively addressing both the local water scarcity and the high-quality standards required for the project.

High-End Quality Unleashes Market Potential

The Fortune Global 500 company, CRH from Ireland, has consistently used crushing and screening equipment from internationally renowned companies. After conducting a comprehensive assessment of NMS, they decided to test the equipment in the rugged granite quarries of Northern Finland.

The Finnish RUDUS Stone Quarry

Finland is renowned for its exceptionally hard rock, and it serves as the global epicenter and headquarters for top-notch rock drilling and crushing equipment. As the procurement head for CRH puts it, “If NMS’s crushers pass Rufus’s test, it’s like receiving a global passport to enter CRH.” In April 2016, a CC300S cone crusher produced by NMS replaced a crusher from an internationally renowned brand and began production at the Helsinki quarry of CRH’s subsidiary, RUDUS. After over a year of evaluation, the equipment’s performance and reliability exceeded customer expectations, reaching international top-tier standards. This success earned the customer’s trust and laid a solid foundation for the subsequent use of NMS’s equipment in various CRH Group projects, including those in Atlanta, the United States, Salt Lake City, the United States, and Quebec City, Canada.

NMS’s Site in America Project

Long as the journey is, we will reach our destination if we stay the course; difficult as the task is, we will get the job done if we keep working at it

In Russia, NMS operates through its Moscow branch, a spare parts warehouse in St. Petersburg, and an after-sales service team, covering regions such as the Republic of Karelia. In response to the production environment of Russian clients, NMS has improved the design and production of crushing and screening equipment models like MC300/MC500 multi-cylinder cone crushers and JC1600 jaw crushers. These machines can operate stably even in the harsh, cold environments of the region, earning significant praise from local customers.

NMS’s Site in Russia Project

NMS’s Spare Parts Warehouse in Russia

In the Democratic Republic of the Congo, NMS’s CC200S single-cylinder cone crusher successfully completed its trial run. In addressing the challenge of crushing stubborn rocks, NMS’s technical service personnel innovatively proposed a new process after discussions with the client. This process ensures that steel balls and iron blocks, which may become embedded or fractured within the stubborn rocks, are separated from the rocks, preventing the iron blocks from entering the cone crusher. This solution addressed a critical issue in the SABC process flow where crushing stubborn rocks was affecting stable production. In the initial stages of the project, the client also acquired NMS’s sled-type jaw crushing station, tire-type jaw crushing station, and vibrating screen. These equipment have operated stably over the years, meeting production and quality standards, and have earned the trust of the client.

NMS’s Site in Malaysia Project

In Malaysia, NMS’s CC400M single-cylinder hydraulic cone crusher is currently being installed at a project site, poised to crush granite. The client initially used NMS’s JC1100 jaw crusher, and the excellent equipment performance led them to choose NMS’s equipment once again to replace their existing equipment from a well-known brand.

Every successful project case serves as a testament to NMS, and the company’s journey into overseas markets continues to unfold.

With more and more countries participating in the co-building of the “Belt and Road” initiative, collaborations span a wider array of fields, presenting both opportunities and challenges for businesses. NMS remains committed to aligning itself with the nation’s development, upholding the business philosophy of “Professional Leadership, Integrity First.” NMS steadfastly follows the path of “International NMS,” prioritizing high-quality solutions for high-end demands, expanding their circle of cooperation, and enhancing the reputation of “Made in China.” In doing so, NMS contribute its part to the high-quality development of the global mining industry.