2022.05.11

2022.05.11

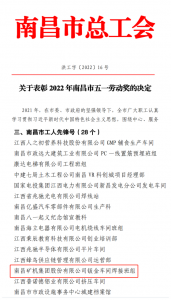

In order to vigorously carry forward the spirit of model worker, labor and craftsman, commend advanced and carry forward the model, recently, Nanchang Federation of Trade Unions announced Decision on Commending Nanchang Labor Day Award in 2022, and the welding team of Nanchang Mineral Systems Co., Ltd. (hereinafter referred to as “NMS”) was awarded “Nanchang worker pioneer”.

It is known that the NMS welding team has 10 employees with an average age of 41.5 years. The team mainly undertakes the welding related work of host of crushing equipment such as JC jaw crusher, CC single cylinder cone crusher, MC multi-cylinder cone crusher, HS impact crusher and VS vertical shaft crusher.

Good enterprise culture and professional ethics are the foundation for sustainable and healthy development of the enterprise. Over the years, under the guidance of the enterprise, the NMS welding team has continuously strengthened the quality of team members, actively carried out on-the-job training, participated in skill competitions and technical competitions, and formed a good atmosphere of competition, learning, catching, helping and surpassing. The team has carried out long-term job skills and knowledge training to make team members fully familiar with the welding process and technical requirements of each series of products, and memorize the welding specifications of each series of products. It has set up team training system to teach new employees in the form of passing, helping and leading, and train skilled welder.

At the same time, the team is innovative and achieving fruitful results in the welding technology innovation of JC jaw crusher. It is very difficult to weld the shells of jaw crusher. The welding quality should meet the requirements of ultrasonic flaw detection, the thermal deformation in the welding process should be considered, and the working time should be reduced as soon as possible to ensure the delivery time. Previously, the welding for shell was manual arc welding, which has many difficulties such as large smoke and dust, long time and low qualification rate. After practice and innovation, the team changed the manual arc welding into carbon dioxide gas shielded welding of EW71 flux cored wire, which greatly improved the efficiency. However, it is difficult to eliminate impurities when fusing flux cored wire and casting, and the production cost of EW71 welding wire is also relatively high. After discussion and comparison between the team and the process department, ER506 solid cored wire was finally used to replace EW71, which raised the production qualification rate to a new high and reduced the cost and repair time cost of welding materials. Through innovation, JC jaw crusher reduces a long-time carbon arc air gouging and root cleaning process that pollutes the working site environment, and the working efficiency is increased by 30% on the original basis.

Photo of welding skill competition in “quality month”

The team has won honorary titles many years and emerged various excellent talents. The award shows Nanchang City’s praise that NMS has attached importance to employee innovation many years and continuously guided employees to base themselves on their posts, learn technology and create efficiency through innovation. NMS will take this opportunity to continue promoting the innovation, give full play to the leading role of model and the advanced, form an atmosphere of innovation and efficiency of all employees, and promote high-quality development of the enterprise.